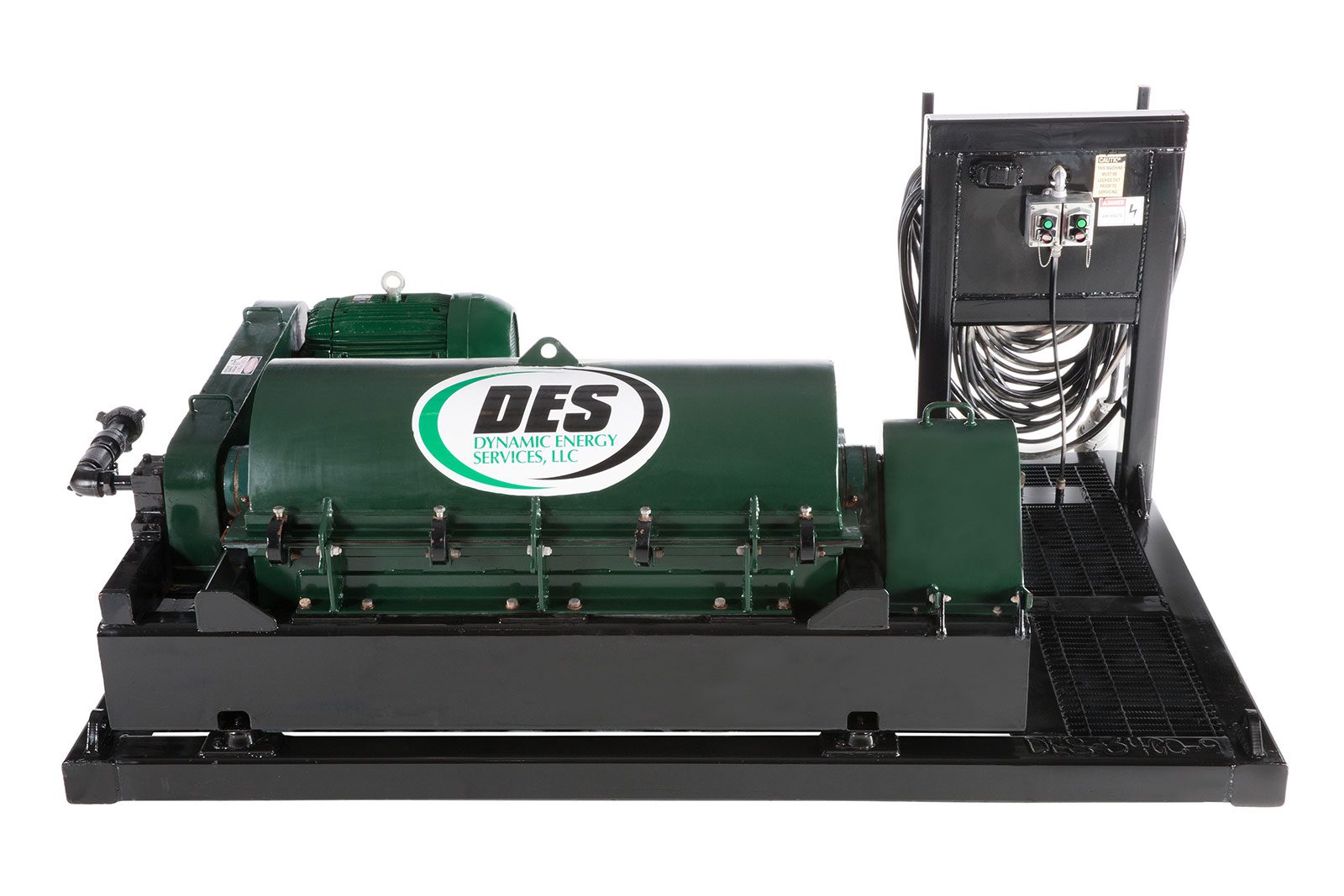

Key Features

- Horizontal decanter design for optimal solids removal

- VFD (Variable Frequency Drive) control for customizable speed and torque

- Heavy-duty stainless steel casings for durability

- Modified components that reduce maintenance and improve performance

- Continuous feed and discharge for uninterrupted operation

How It Works

Slurry enters the feed chamber inside the auger, where an accelerator plate distributes it into the spinning bowl. Centrifugal force separates heavier solids, which are pushed toward the solids discharge ports by the rotating auger. Clean fluid exits through adjustable eccentric ports and is either recycled into the mud system or routed elsewhere.

Why It Matters

By improving solids separation and reducing fluid loss, DES centrifuges help operators:

- Cut down on disposal costs

- Extend the life of drilling equipment

- Improve drilling fluid performance

- Reduce downtime and maintenance

Centrifuge Models

| Model | HP | Max Capacity (GPM) | Bowl Size | Notes |

|---|---|---|---|---|

| DES-1850 | 50 HP | Up to 250 GPM | 18″ x 50″ | |

| DES-3400 | 40 HP | Up to 250 GPM | 14″ x 48″ | Bearing machine |

| DES-5800 | 75 HP | Up to 450 GPM | 16.5″ x 55.5″ | Bearing machine |

| DES-7800 | 125 HP | Up to 600 GPM | 20″ x 70″ | High-capacity bearing model |

All models are VFD-controlled, with the 3400, 5800, and 7800 models built with bearing assemblies for higher RPMs and increased G-force output.